RoArm-M3

- Mã sản phẩm: RoArm-M3-S

- Nhà sản xuất: Waveshare

- Website hỗ trợ: https://www.proe.vn

WIKI: www.waveshare.com/wiki/RoArm-M3

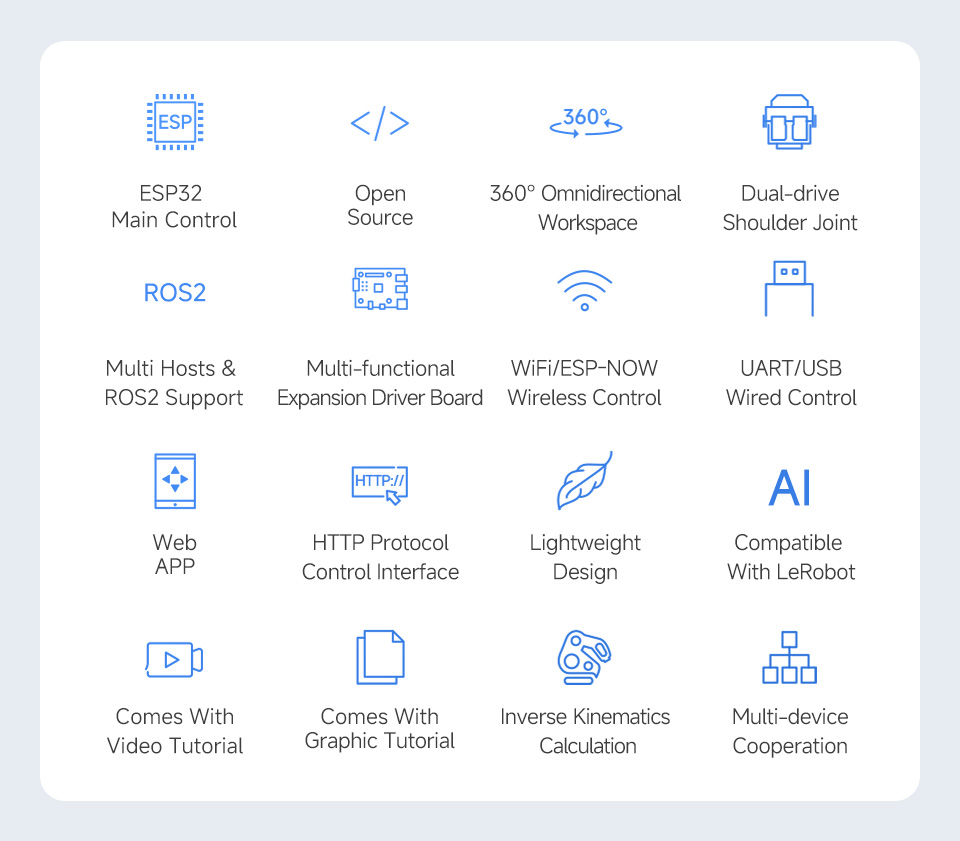

5 + 1 DOF High-Torque Serial Bus Servo Robotic Arm Kit, Based On ESP32, 2-DOF Wrist Joint, Supports Flexible Expansion And Secondary Development, Wireless Control, Compatible With LeRobot

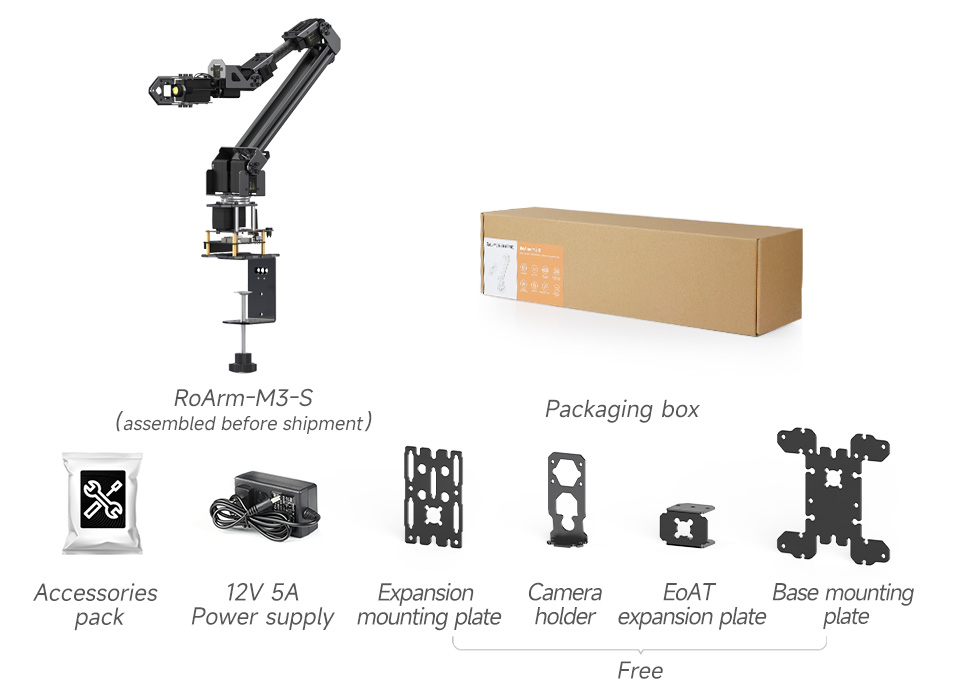

RoArm-M3-S

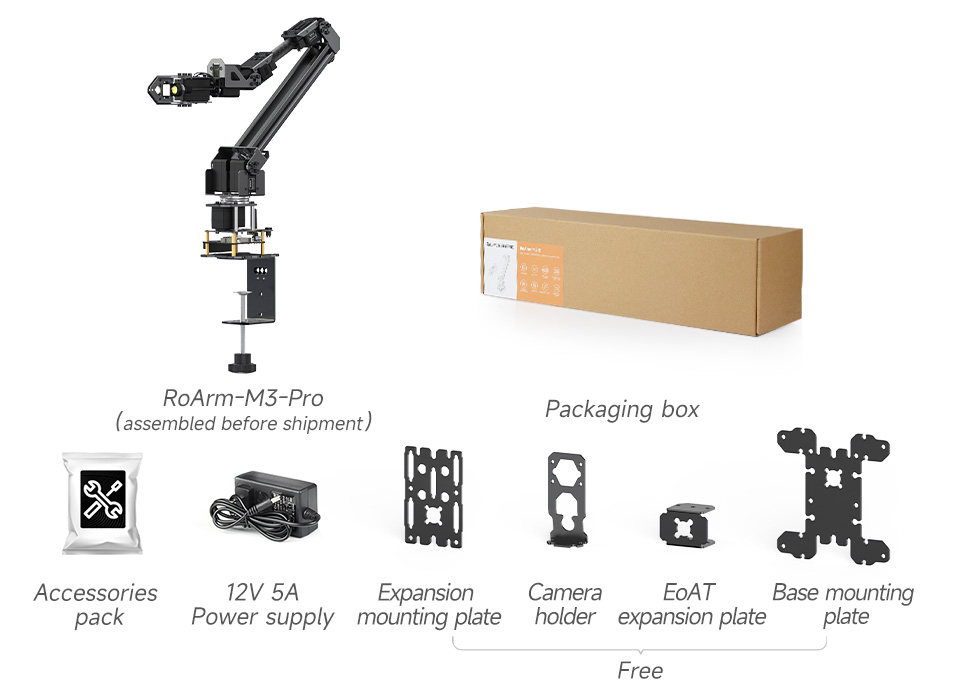

RoArm-M3-Pro

RoArm-M3

5 + 1 DOF High-Torque Serial Bus Servo Robotic Arm

Supports flexible expansion and secondary development

* for reference only, please refer to the Package Content for the detailed part list

Product Introduction

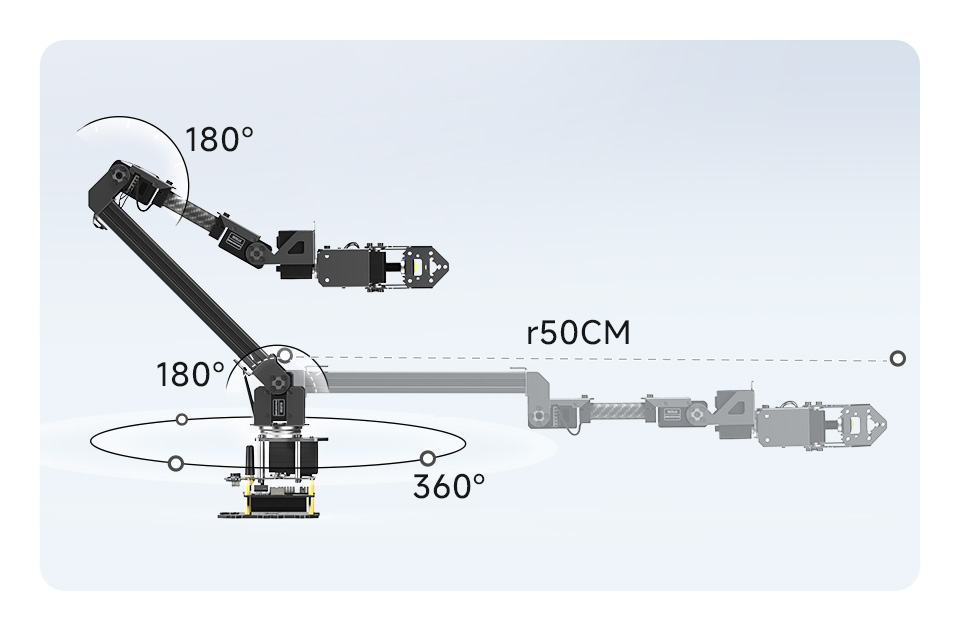

RoArm-M3 series is a 5 + 1 DOF smart robotic arm designed for innovative applications. Adopts lightweight structure design with an effective payload of 0.2kg@0.5m, it can be flexibly mounted on various mobile platforms. Adopts a 360° omnidirectional base combined with five flexible joints to create a workspace with 1-meter diameter.

The joint direct-drive design enhances repositioning precision and also improves structural reliability, with innovative dual-drive technology doubling the shoulder joint torque. Onboard ESP32 MCU main control module, supports multiple wireless control modes, and provides control interfaces and rich communication protocols for easily connecting to various devices.

Provides a user-friendly and cross-platform WEB application that integrates a simple and visualized coordinate control mode, making it easier to get started. Comes with rich graphic and video tutorials to help you learn and use it quickly. Compatible with ROS2 and various host computers, supports various wireless and wired communication modes. Comes with expansion plates, supports customizing the EoAT (End of Arm Tooling) to meet innovative application requirements.

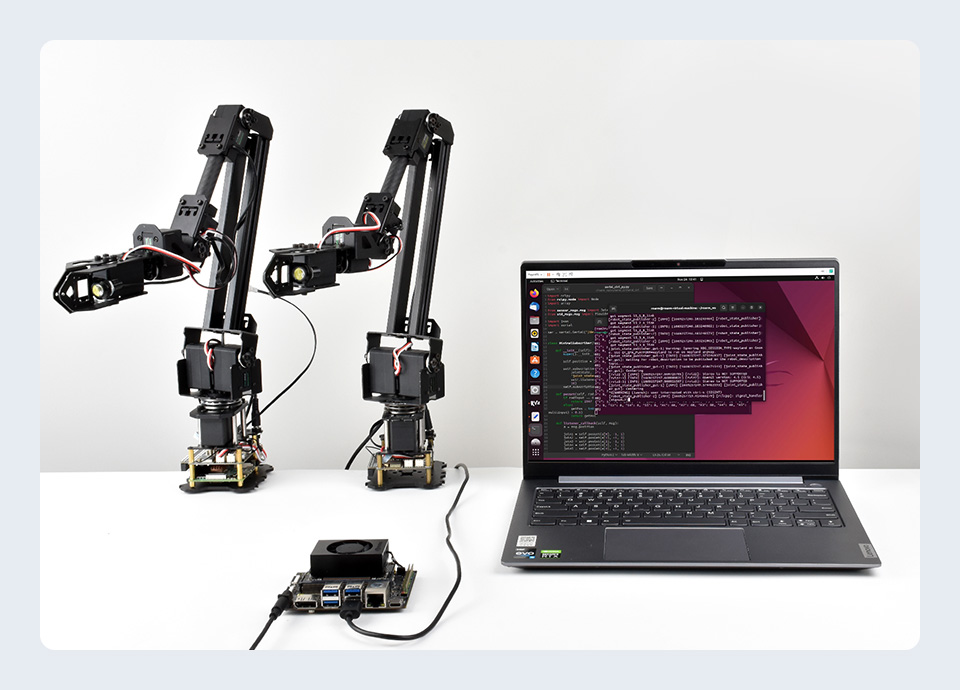

At the same time, the RoArm-M3 series also supports the popular AI robotic arm project LeRobot, integrating its pretrained models, datasets with demonstrations, and simulation environments, providing strong support for research directions such as Deep Learning, Imitation Learning, and Reinforcement Learning. By utilizing the demos and algorithm libraries of LeRobot, developers can quickly deploy intelligent algorithms onto the RoArm-M3, further expanding the possibilities for innovative applications.

RoArm-M3 series achieves an excellent balance between lightweight, user-friendliness, expandability, and open innovation, it is a multi-functional robotic arm that integrates intelligent control, human-machine interaction, and customizable development. Ideal for applications that require a combination of flexibility, expandability, and user-friendliness.

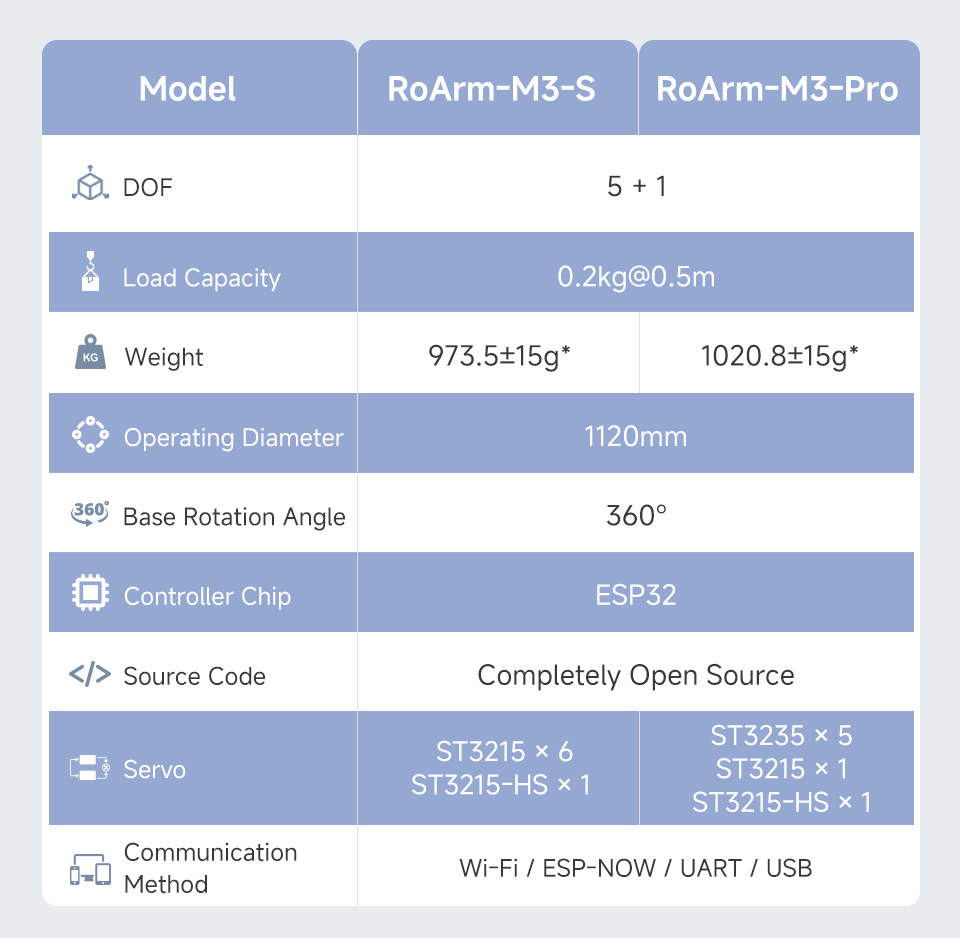

Version Options

Provides options for RoArm-M3-S / RoArm-M3-Pro. The RoArm-M3-Pro is equipped with 5x all-metal ST3235 bus servos, offering a more rugged body and stable backlash that won't increase with use, enhancing product durability.

Parameter Comparison

* Not including the weight of the table edge fixing clamp (290±10g).

Compatible with the popular AI robotic arm project - LeRobot

The RoArm-M3 robotic arm series supports the open-source LeRobot framework on Hugging Face, providing core resources such as pretrained models, datasets with human collected demonstrations, and simulation environments. When combined with the N-VIDIA Jetson Orin NX motherboard or a PC with an N-VIDIA discrete GPU, users can experience the complete process of Imitation Learning and Reinforcement Learning projects.

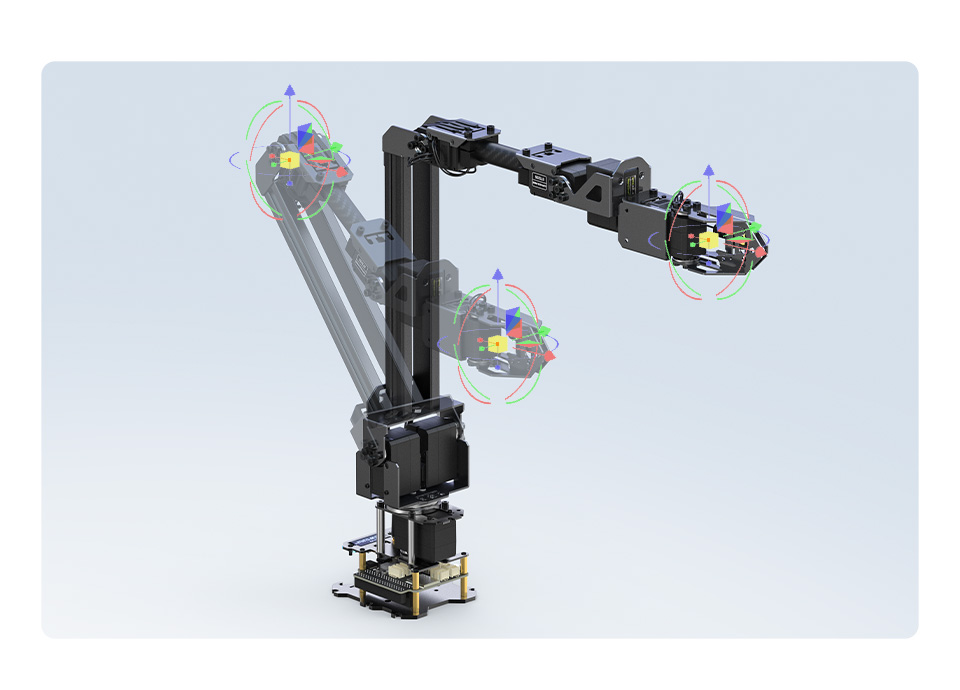

Flexible joints × omnidirectional space

Adopts 360° rotation base and flexible joints to create an omnidirectional operating space with 1-meter diameter, allowing the Robotic Arm to move freely in all directions

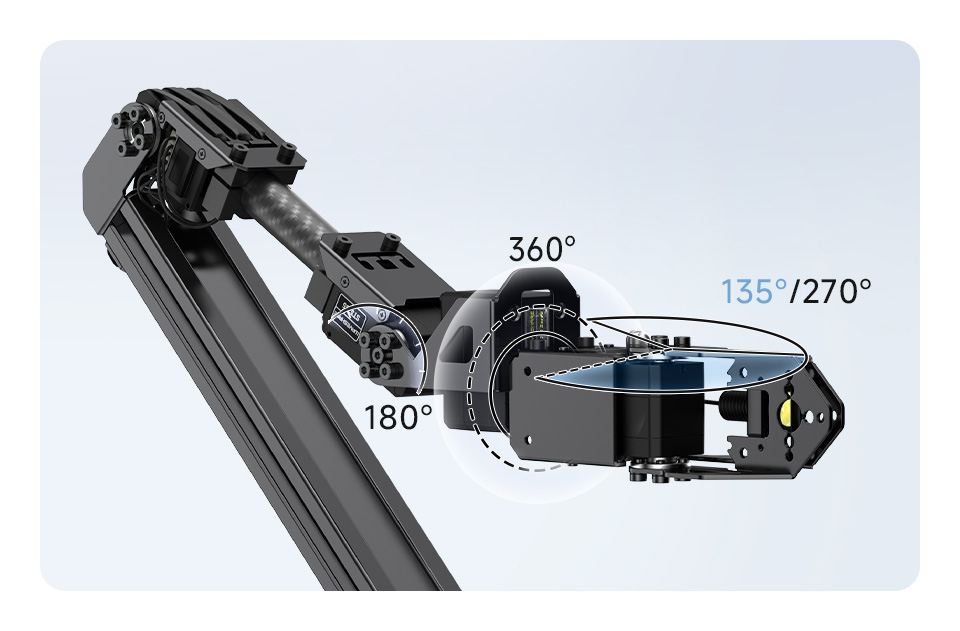

2 DOF Wrist Joint + EoAT

for more flexible clamping

Equipped with 2 DOF wrist joint with pitch + horizontal rotation support, enables seamless coordination with the EoAT for multi-dimensional clamping and operation

Easy to control via

Cross-platform Web Application

No App installation required, access after entering the address. Allows users to connect and control RoArm-M3 via mobile phones, tablets and computers by clicking the buttons on the Web App. Supports secondary development of this open-source Web App to customize the user interface and add new functions.

Completely open source for

secondary development

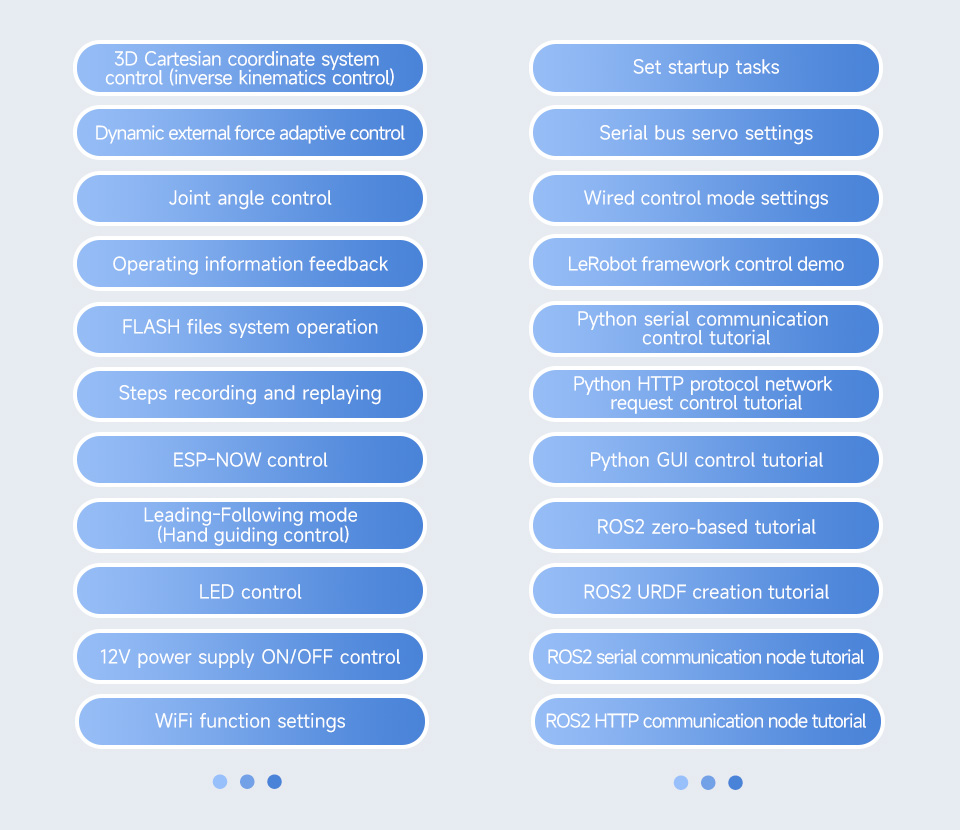

Completely open source for the control codes and communication interface documents of RoArm-M3 series, supports multiple languages and devices for secondary development. Provides modularized demos and tutorials for zero-based users, easy to get started.

joint Direct-drive design

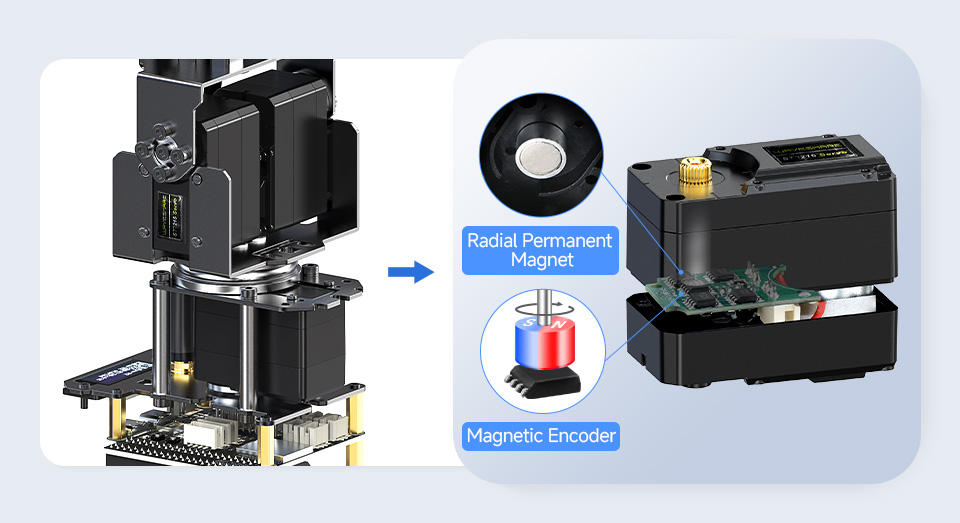

The Feedback precision is up to 0.088°

The joint angle feedback can be obtained directly via the 12-bit high-precision magnetic encoder without any reduction groups, which is more accurate, and the actual position of the current target point can be calculated based on the joint angle feedback.

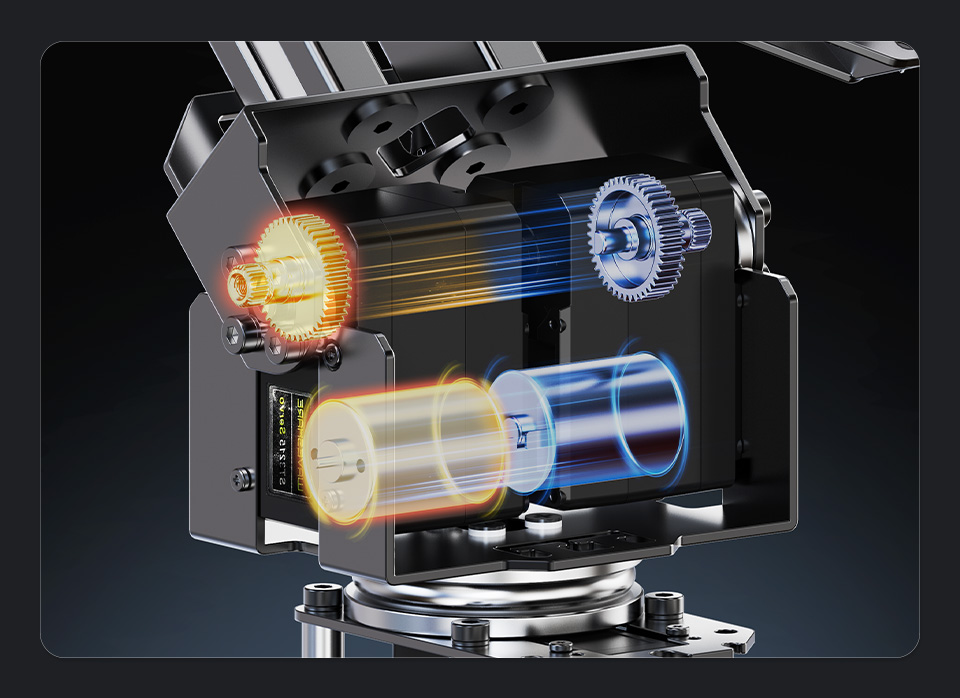

Innovative dual-drive technology

doubles the shoulder joint torque

We have developed a dual-drive control algorithm that allows the two servos at the shoulder joint to coordinate their output torque effectively, significantly enhancing the power and the overall load capacity of RoArm-M3 Series

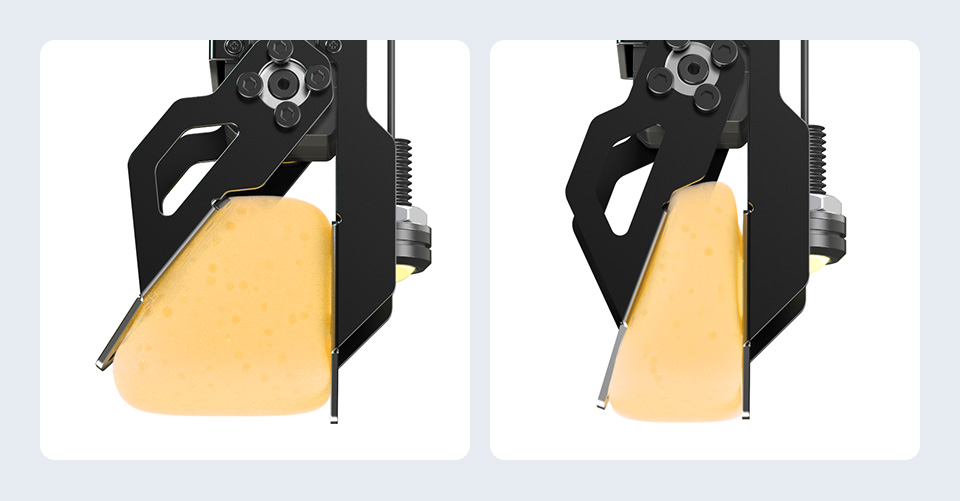

Direct-drive clamp enables precise force control

The direct-drive clamp design allows precise control of the clamping force in the program, suitable for clamping delicate objects without applying excessive force

Dynamic external force

adaptive control

After enabling this function, you can limit the maximum torque for each joint. When the external force applied to the joint exceeds the torque threshold (configurable), the robotic arm will rotate in response to the external force, and will return to the specified position when the external force decreases below the torque threshold.

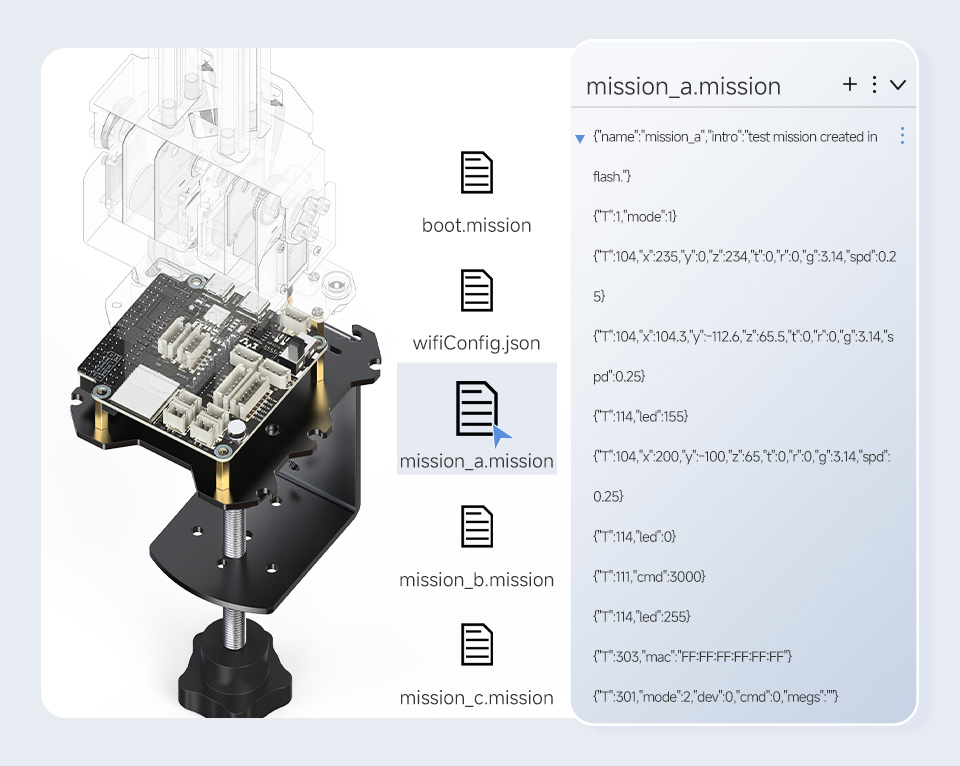

One-click automatic recording

Easy to create actions

RoArm-M3 can save JSON instructions for robot control as task files. The task files can be saved in the Flash of ESP32, which will not be lost in case of power loss. The robotic arm can perform complex and repetitive operations by calling these task files.

Accurately reach the target by entering the coordinates

Open source for inverse kinematics control algorithm in the three-dimensional Cartesian coordinate system. After entering the target position, the robot arm can accurately reach the target point by using the inverse kinematics function to calculate the rotation angle of each joint.

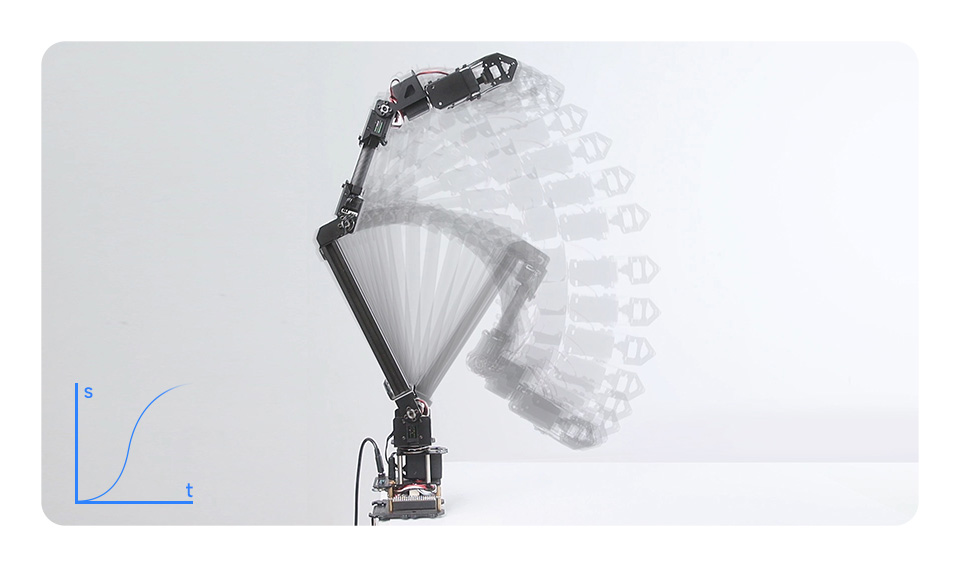

Curve Velocity Control for

Smoother movement

We use the curve velocity control algorithm to make the robotic arm move smoother and more naturally, without oscillations during start and stop

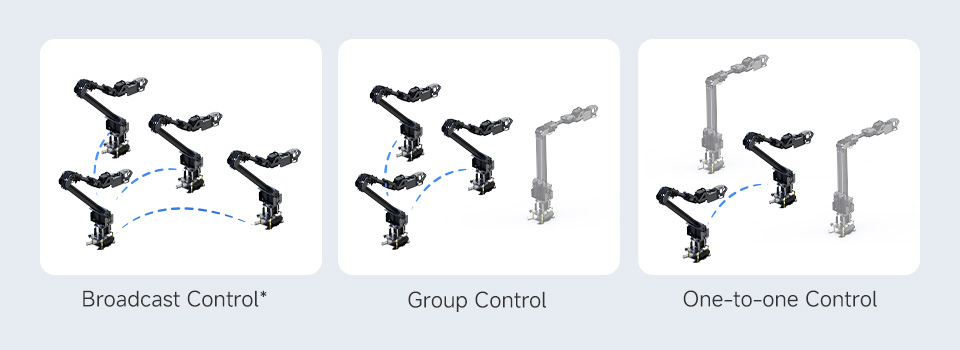

ESP-NOW wireless control

Low-delay remote collaboration

ESP-NOW is a low-delay ad hoc wireless communication protocol, without the need of Network infrastructures. You can use one robotic arm to wirelessly control other robotic arms, and the control methods can be set as broadcast control, group control, and one-to-one control.

* Note: The broadcast control has no limitation for the number of controlled devices, while the group control allows up to 20 devices. Please refer to the WIKI for more details.

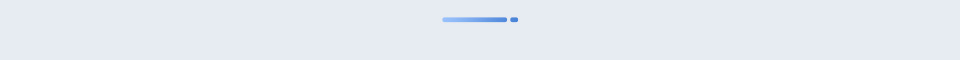

Supports Leading-following control mode based on ESP-NOW

In the Leading-following control mode, the Leader robotic arm will send its joint angle information to other robotic arms via ESP-NOW communication. The other robotic arms which are in ESP-NOW Follower mode will imitate the same actions as the Leader in real time.

multiple control interfaces,

multiple devices and languages Support

RoArm-M3 series can be controlled not only by the WEB application, but also supports using other controllers to send JSON commands via HTTP protocol network request, serial communication, or USB communication for controlling and obtaining feedback.

Multiple installation methods for Integrating into Your Application

Provides multiple installation schemes and related secondary development resources, suitable for different usage scenarios and can be flexibly integrated into your projects and applications

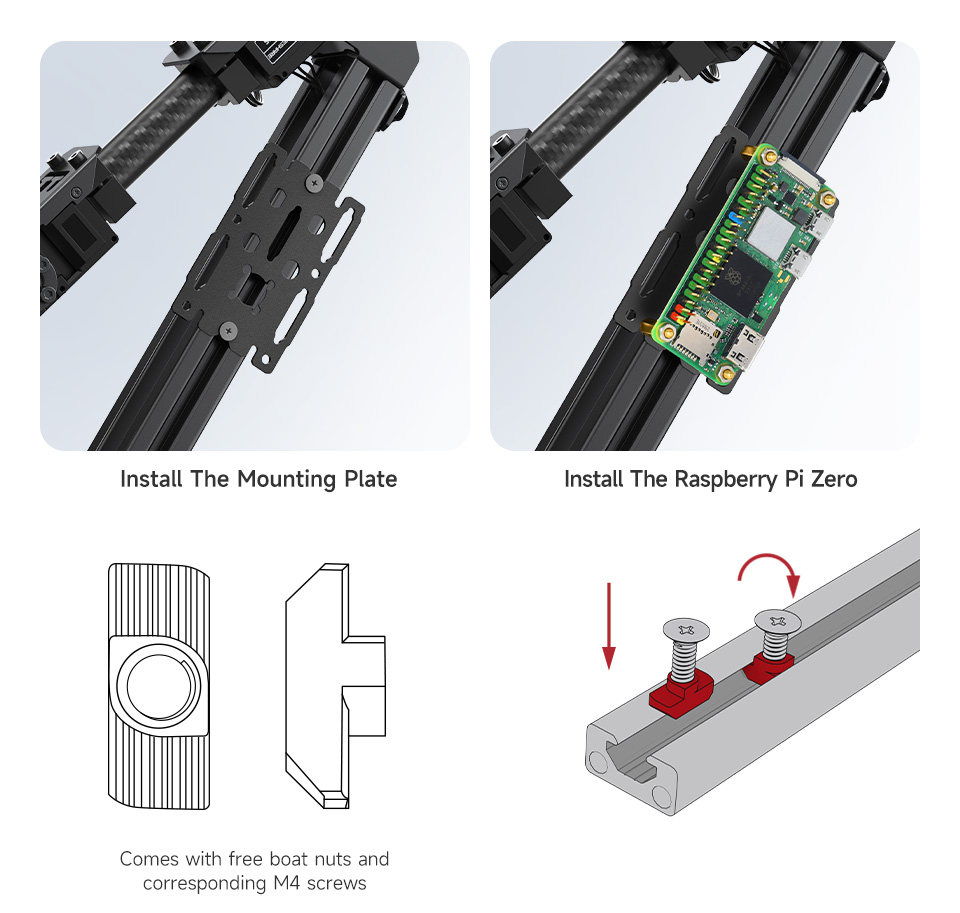

Easy To install different peripherals

The main structure of the upper arm adopts two 1020 European standard aluminum rails, supports installing additional peripherals via the boat nuts to meet different needs. Comes with boat nuts and corresponding M4 screws for easy installation.

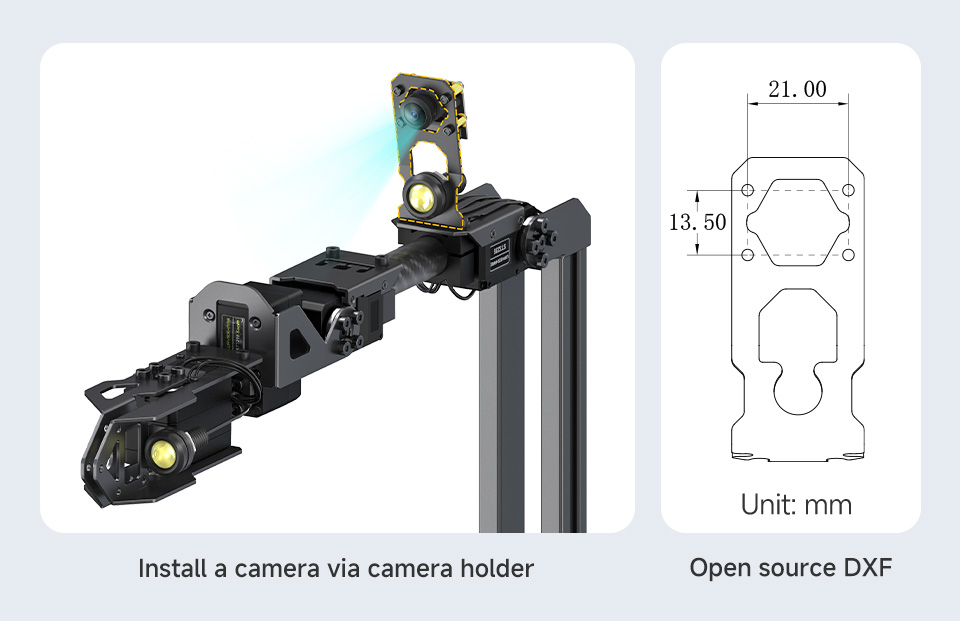

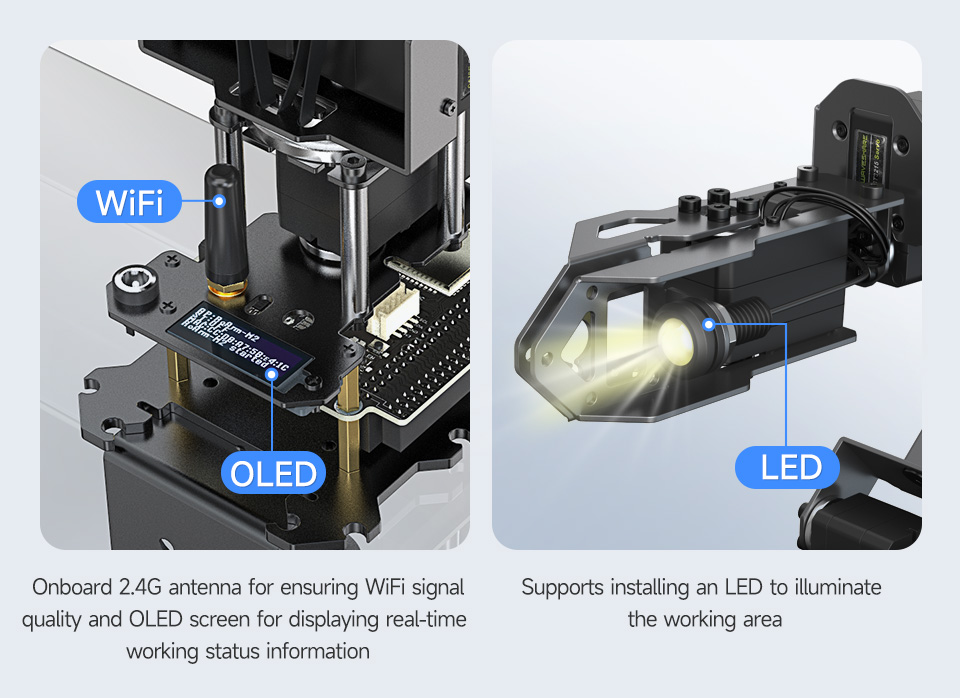

Supports installing a camera to extend visual applications

Comes with a camera holder and open source for the related drawings. You can directly install a camera with the corresponding size or other cameras with an adapter

* for reference only, only the LED light is included.

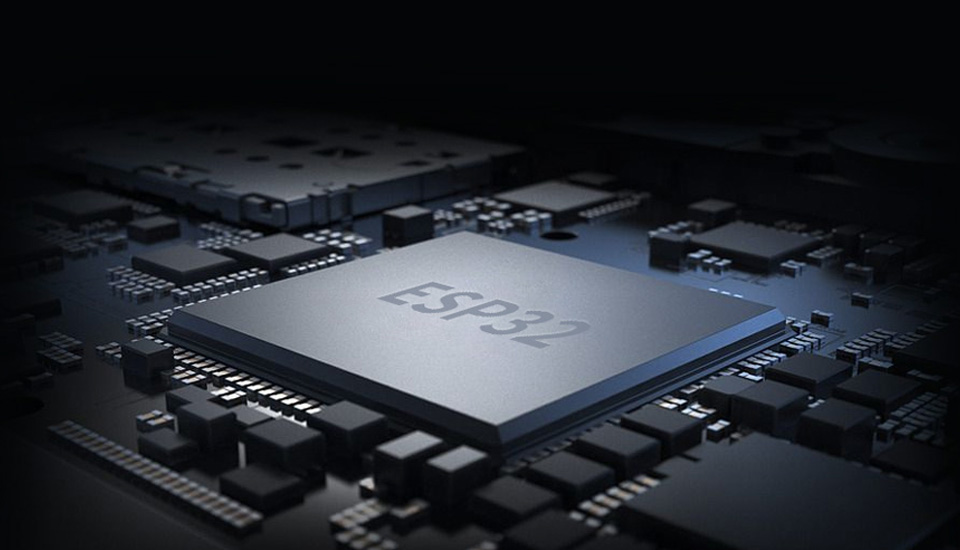

Onboard ESP32 Main control board

Adopts ESP32 powerful main control MCU, supports Multiple wireless communication protocols, with a large amount of open source resources to help secondary development of innovative applications

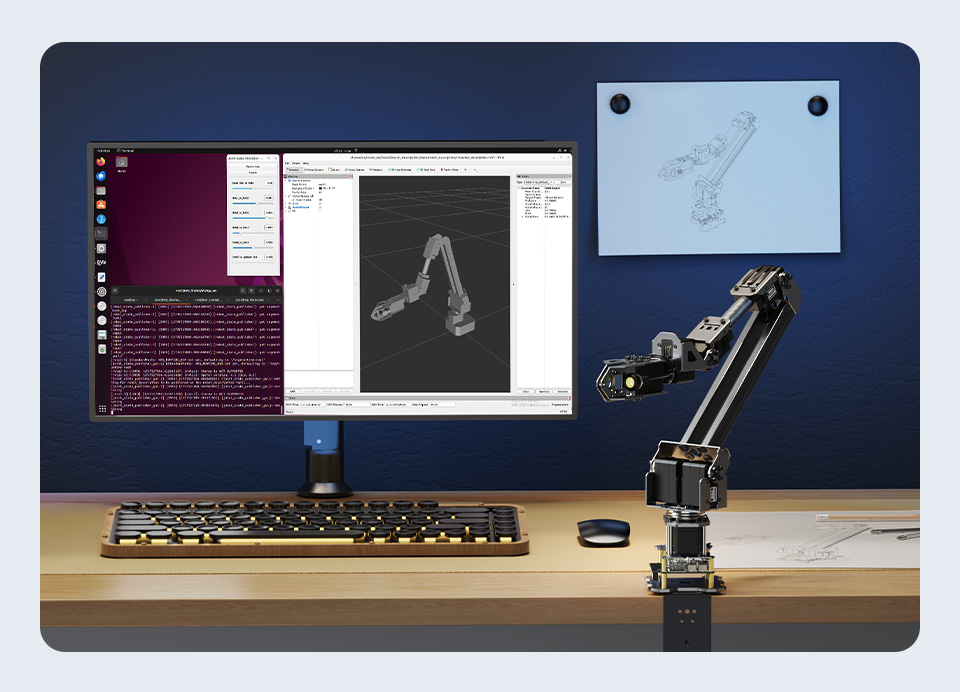

Compatible with ROS2, Provides model establishment File and supports multi-device cooperation

Provides communication nodes of ROS2, URDF model description file and zero-based tutorial of ROS2

rich tutorial resources for

secondary development

We provide complete unit tutorials and cases, including various functions and common application scenarios, to help users get started quickly for secondary development

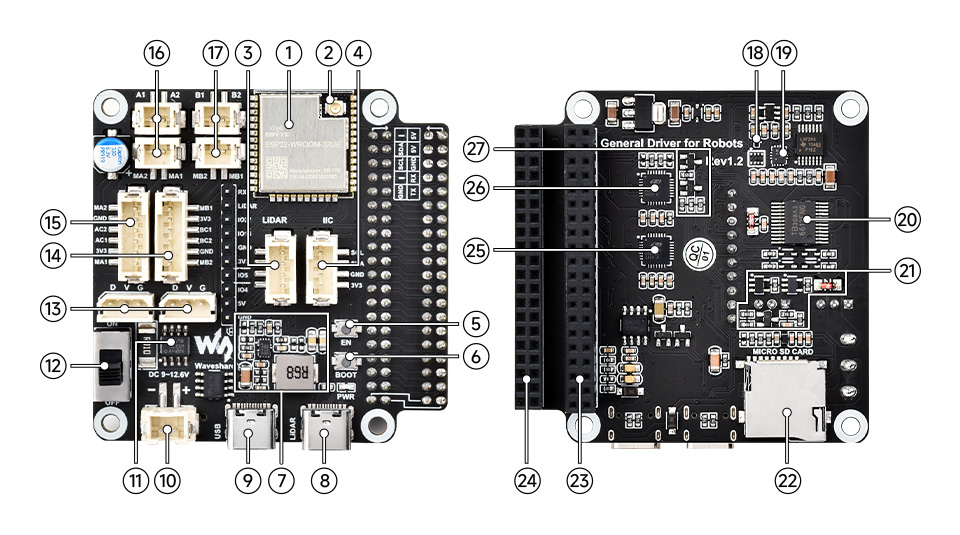

General Driver Board for Robots

Onboard rich interfaces and resources for innovative development and functional expansion

- ESP32-WROOM-32 controller module

Can be developed using Arduino IDE - IPEX 1 WIFI connector

For connecting WIFI antenna to increase the wireless communication distance - LIDAR interface

Integrated LIDAR adapter function - I2C peripheral expansion interface

For connecting with OLED screen or other I2C sensors - Reset Button

Press and release to reboot the ESP32 - Download button

Press when powering on to enter download mode - DC-DC 5V voltage regulator circuit

Provides power supply for host computers such as Raspberry Pi or Jetson nano - Type-C port (LADAR)

LIDAR data transmission - Type-C port (USB)

ESP32 communication interface, for uploading programs to ESP32 - XH2.54 power port

Support DC 7~13V input, can directly power the serial bus servos and motors - INA219

voltage/current monitoring chip - Power ON/OFF

External power supply ON/OFF - ST series serial bus servo interface

For connecting with ST3215 / ST3235 serial bus servo - Motor interface PH2.0 6P

Group B interface for motor with encoder

- Motor interface PH2.0 6P

Group A interface for motor with encoder - Motor interface PH2.0 2P

Group A interface for motor without encoder - Motor interface PH2.0 2P

Group B interface for motor without encoder - AK09918C

3-axis electronic compass - QMI8658C

6-axis motion sensor - TB6612FNG

Motor Control Chip - Serial bus servo control circuit

for controlling multiple ST3215 serial bus servos and obtaining servos feedback - TF card slot

Can be used to store logs or WIFI configurations - 40PIN GPIO header

For connecting with Raspberry Pi or other host boards - 40PIN extended header

Easy to use the GPIO pins of Raspberry Pi or other host boards - CP-2102

UART to USB, for LIDAR data transmission - CP-2102

UART to USB, for ESP32 communication - Automatic download circuit

For Uploading programs to the ESP32 without pressing the EN and BOOT buttons

Diversified onboard resources

Supports function expansion

Integrated with INA219 battery voltage Monitoring and 9-axis IMU sensor, supports function expansion and innovation

Mouse drag-and-drop interaction

Provides Web applications and desktop software (open-source programs developed by Python), supports setting action instructions when the mouse is pressed and released to control the robotic arm flexibly

Specifications

| DOF | 5 + 1 |

|---|---|

| Work space | Horizontal diameter: 1120mm (Max, 360° omnidirectional), Vertical: 798mm (Max) |

| Operating voltage | 12V 5A power supply, supports 3S Lithium batteries (NOT included) |

| Load capacity | 0.2kg@0.5m |

| repositioning precision | ~ 5mm |

| Servo rotation speed | 40rpm (no-load, no torque limit) |

| Operating range | BASE-360°, SHOULDER-180°, ELBOW-225°, HAND-135°/270° |

| Drive type | TTL Serial bus servo, direct-drive joint |

| Servo numbers | 7 |

| Joint angle sensor | 12-bit 360° magnetic encoder |

| Servo torque | 30KG.CM @12V, 20KG·CM @ 12V (EoAT) |

| Joint feedback information | servo status, joint angle, rotation speed, joint load, servo voltage, servo current, servo temperature and servo working mode |

| Main control | ESP32-WROOM-32 |

| Main control module features | WiFi, BT, Dual Core, 240MHz |

| Wireless control mode | 2.4G-WiFi, ESP-NOW |

| Wired control mode | USB, UART |

| Manual operation mode | WEB control interface |

| Host operation mode | UART / USB / WEB commands in JSON data format |

| Host support | USB connection devices such as Raspberry Pi, Jetson Orin Nano, and PC. |

| EoAT function | clamp function by default, can be changed as an additional degree of freedom |

| LED power | ≤1.5W |

| OLED screen size | 0.91inch |

| Other functions | 2-ch 12V power supply switch, 9-DOF IMU |

| Robotic arm weight | RoArm-M3-S: 973.5±15g RoArm-M3-Pro: 1020.8g±15g (Not including the weight of the table edge fixing clamp) |

| table edge fixing clamp weight | 290±10g |

| Supported table edge thickness of the clamp | 72mm |

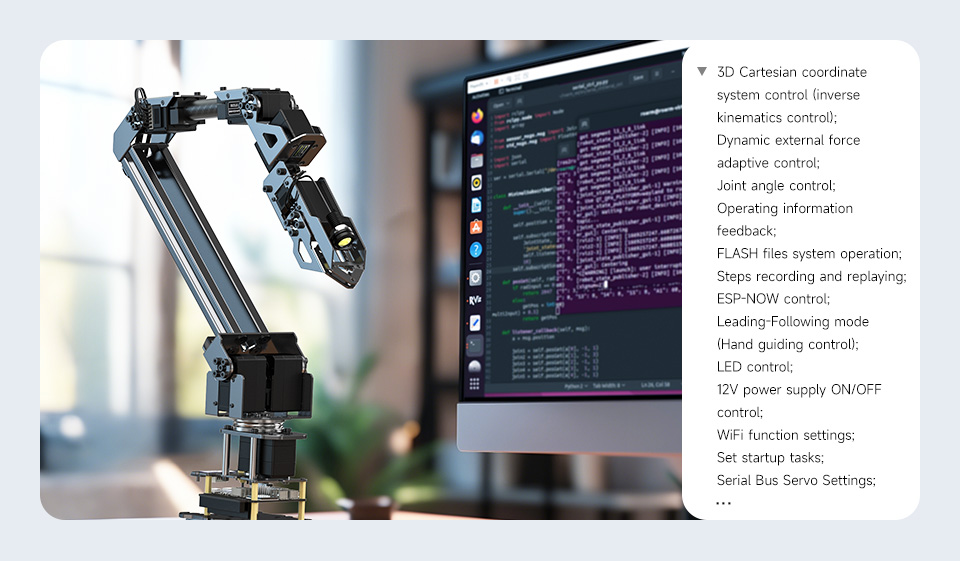

| Demo | 3D Cartesian coordinate system control (inverse kinematics control); Dynamic external force adaptive control; Joint angle control; Operating information feedback; FLASH files system operation; Steps recording and replaying; ESP-NOW control; Leading-Following mode (Hand guiding control); LED control; 12V power supply ON/OFF control; WiFi function settings; Set startup tasks; Serial bus servo settings; Feedback mode setting, etc. (Note: Please refer to the WIKI for more details) |

Product & Packaging show

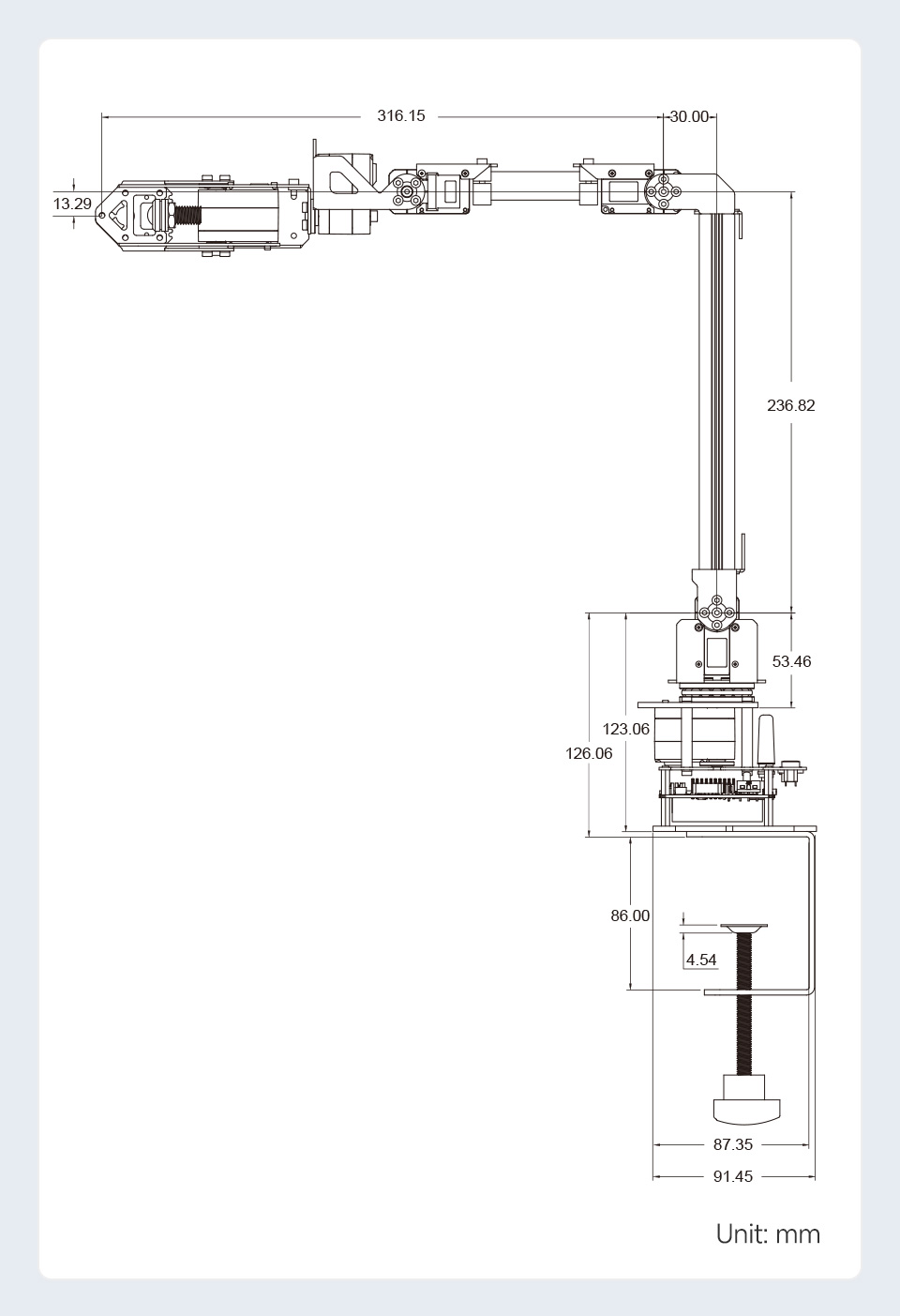

Dimensions

Điện tử ProE cung cấp linh kiện điện tử, thiết bị điện tử , linh kiện IoT chính hãng. ProE cung cấp dịch vụ đặt hàng linh kiện điện tử, thiết bị điện tử chính hãng theo yêu cầu cụ thể của khách hàng. Liên hệ : contact@proe.vn, SĐT: 0938946849

Website: www.proe.vn

Diễn đàn: https://www.facebook.com/groups/278263459284765/

Youtube Chanel: ProE Youtube

Facebook: ProE Facebook